Combustion technology

Ready to fire for low-pollution systems.

We implement environmentally conscious solutions for economical power plant operation.

There is a strong demand for low-emission combustion systems in thermal plants due to growing environmental awareness and increasing demands for economical power plant operation. The changing energy mix coupled with an increasingly volatile percentage of renewables still require flexible firing systems, at least in the medium term. For us, increasing the load gradients and the load range of furnaces is familiar territory. We have had a burning passion for these topics for a long time as we have already successfully developed, planned, delivered and commissioned numerous low-emission furnaces.

Our range of services include:

-

Conversion and modernisation of existing firing systems

-

New plants

-

Preparing studies for fuel changeover

-

Change in performance

-

Adjustment of control range

-

NOx reduction

-

Preparation of approval documents

-

Consultation services for customers with firing problems

-

Manufacturer-independent spare parts service

-

Emission measurements

-

Furnace inspection

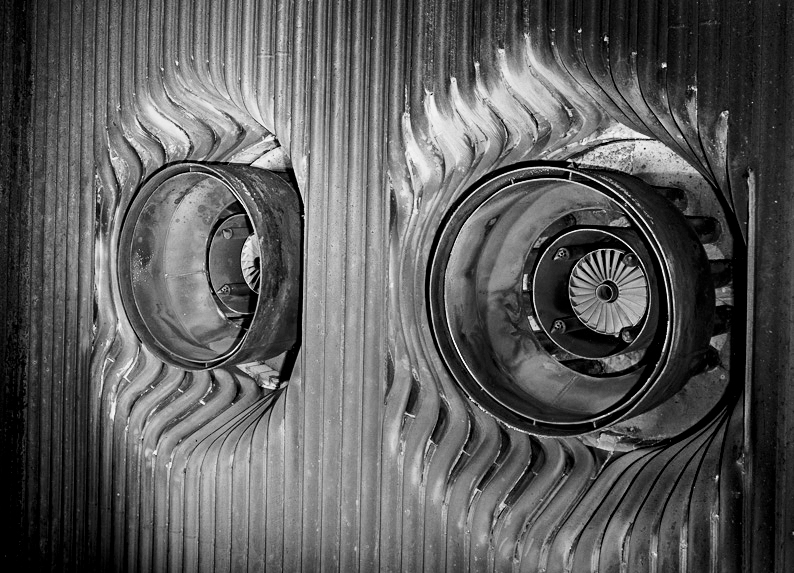

Burners and fuels

We design tailor-made burners to suit the new firing system for your boiler by combining them with the optimum combustion air supply.

Burner versions:

-

Dust burners (lignite)

-

Oil burners

-

Gas burners

Ancillary plants

The burners and the combustion air system are at the heart of the firing systems, and of course we also have the necessary expertise for ancillary peripheral systems.

These include:

-

Tank systems, coaling plants

-

Pump and preheating stations

-

Supply lines

-

Gas pressure reducing stations

-

Valve stations

-

Burner valves

-

Ignition devices

-

Flame monitoring

-

Combustion air supply

-

Flue gas recirculation systems

-

Measuring and controlling technology

-

Fail-safe burner controls